Ensuring Safety and Compliance

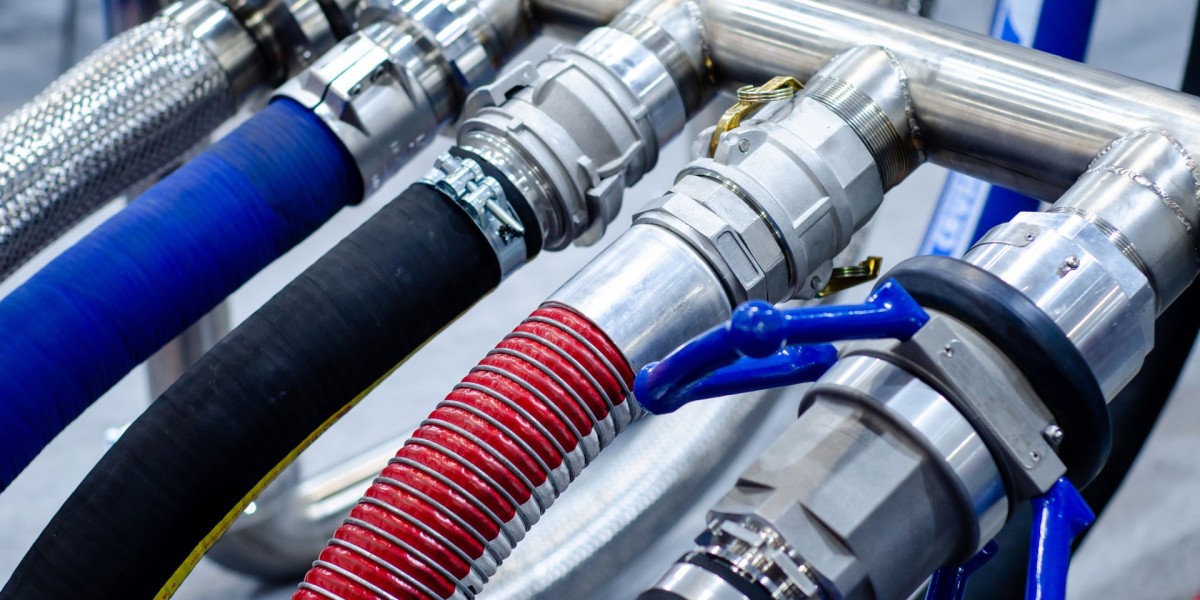

In industries where the transfer of hazardous materials is commonplace, safety is paramount. Industrial hoses are engineered not only for efficiency but also for safety. Manufacturers adhere to stringent standards and regulations to ensure that hoses meet specific requirements for pressure ratings, material compatibility, and environmental conditions. Regular inspections and maintenance further ensure that hoses remain in optimal condition, minimizing the risk of leaks, spills, and accidents.

Innovations Driving Efficiency

As technology continues to advance, so too do Industrial Hoses and their associated components. Innovations such as lightweight materials, anti-static properties, and abrasion-resistant coatings enhance the performance and longevity of hoses, reducing downtime and maintenance costs for manufacturers. Moreover, the integration of smart sensors and monitoring systems enables real-time tracking of hose conditions, allowing for proactive maintenance and minimizing the risk of unexpected failures.

Environmental Considerations

In an era increasingly focused on sustainability and environmental responsibility, industrial hose manufacturers are also embracing eco-friendly practices. From using recyclable materials in hose construction to designing products with minimal environmental impact, the industry is striving to reduce its carbon footprint while maintaining the highest standards of performance and reliability.

Get more insights on Industrial Hose