Packaging plays a vital role in protecting products, extending shelf life, and enhancing the consumer experience. However, traditional packaging materials have several limitations and environmental impact concerns. Next generation packaging aims to address these issues through groundbreaking material innovations and design approaches.

Sustainable and Biodegradable Materials

One of the key focus areas of Next Generation Packaging is utilizing sustainable and biodegradable materials that reduce environmental footprint. Polymers derived from plant-based sources like cellulose, starch, and polymers are increasingly being used for flexible and rigid packaging. These plant-polymers can fully degrade after use without releasing toxic residues. Additionally, companies are also exploring the use of agricultural byproducts and waste materials in packaging production. The use of such renewable and organic materials helps cut down reliance on fossil fuels and reduces plastic waste in landfills and oceans.

Advanced Barrier Technologies

Another limitation of traditional packaging is inadequate protection against external factors like moisture, oxygen, grease etc. that can impact product quality and shelf life. Next generation barrier technologies use innovative material combinations and enhanced coating approaches to provide high barrier functionality. These include oxide and mineral layer coatings, biomimetic structures, and nanomaterial enabled layers that can block penetration of gases, liquids and other agents. Advanced barrier packaging plays a vital role in preserving perishable food and pharmaceutical products for longer duration without preservatives or refrigeration.

Intelligent and Active Packaging Systems

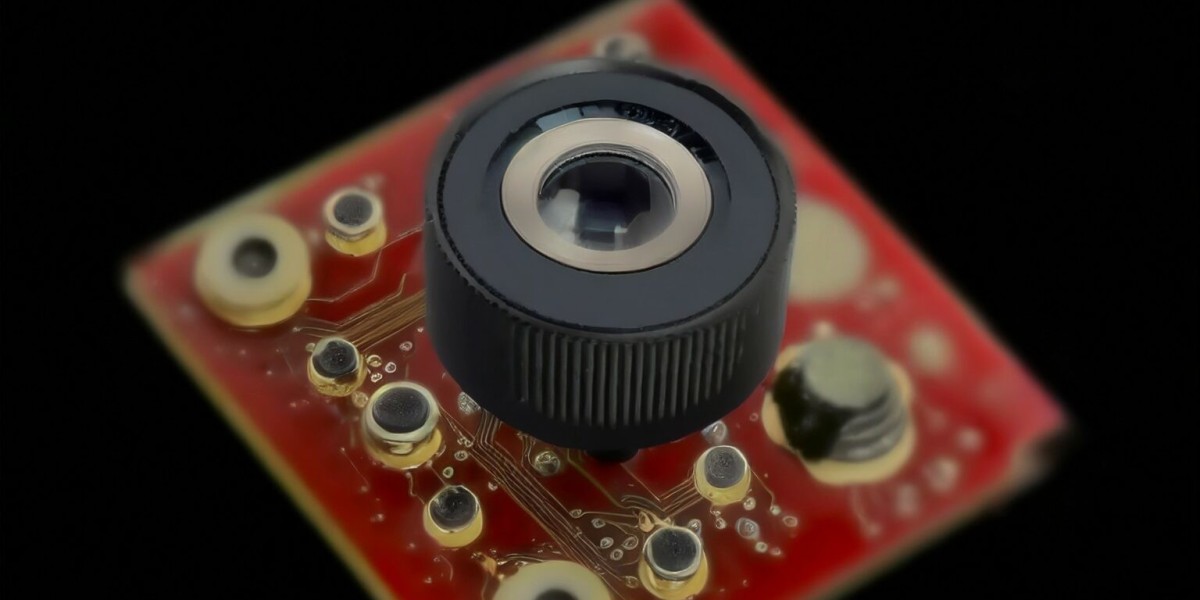

Next generation packaging is also focusing on developing intelligent and active packaging systems with integrated sensing and communication capabilities. These systems can monitor critical parameters like temperature, moisture, atmospheric composition around the product in real time. Embedded electronics, wireless sensors and communication protocols enable remote monitoring of product condition during transit and storage. Intelligent labels powered by printed electronics or flexible batteries can display critical product information. Some active packaging systems also release preservatives or absorb ethylene and other deteriorating agents to extend shelf life. Such intelligent traceability aids supply chain management while active functionality enhances product protection.

Get more insights on Next Generation Packaging