In the world of machining, efficiency, precision, and versatility are paramount. Broaching tools stand out as indispensable assets, offering innovative solutions to a variety of machining challenges.

Understanding Broaching Tools:

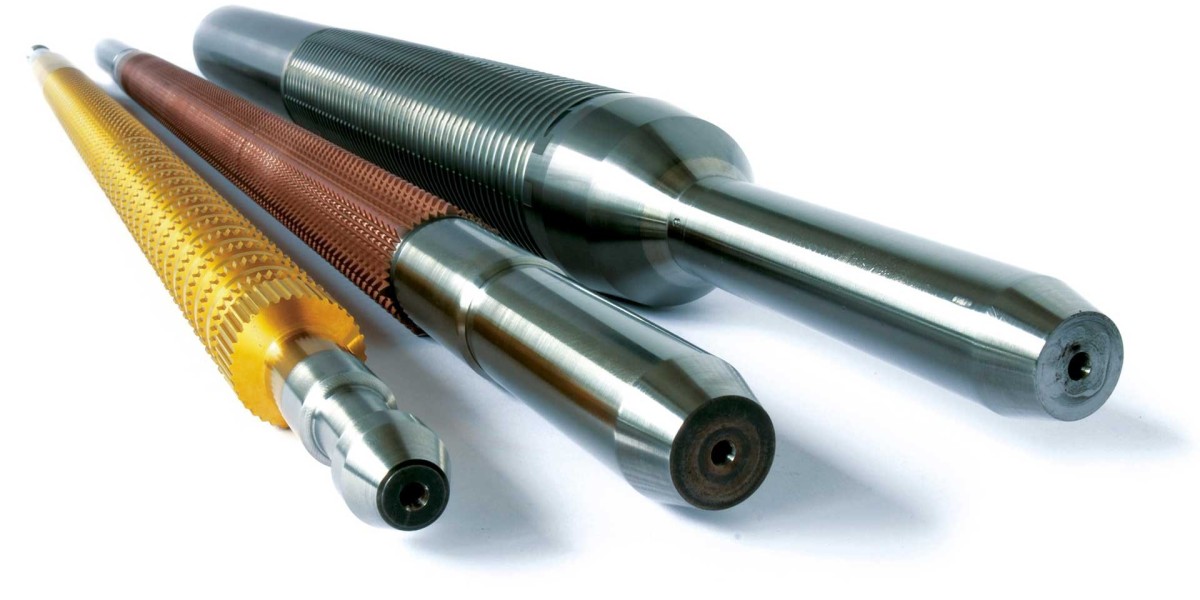

Broaching is a machining process that involves removing material from a workpiece using a specialized tool called a broach. Broaches come in various shapes and sizes, each designed to perform specific cutting operations with remarkable accuracy and efficiency. From keyways and splines to gears and slots, broaching tools excel in producing precise internal and external profiles on a wide range of workpieces.

Versatility in Application:

One of the key strengths of Broaching Tools lies in their versatility. Whether it’s shaping intricate internal features in automotive components or creating precise slots in aerospace parts, broaching tools adapt to diverse machining requirements with ease. Their ability to perform multiple cutting operations in a single pass streamlines the manufacturing process, reducing production time and costs while maintaining exceptional quality standards.

Precision Engineering for Complex Profiles:

Broaching tools are synonymous with precision engineering, enabling the creation of complex profiles with unparalleled accuracy. Unlike other machining methods that may struggle with intricate geometries, broaching tools excel in producing sharp corners, tight tolerances, and smooth surface finishes. This precision is particularly valuable in industries where component performance and reliability are critical, such as aerospace, automotive, and medical device manufacturing.

Innovations Driving Efficiency:

Advancements in tool design, materials, and manufacturing techniques have propelled broaching tools to new heights of efficiency and performance. High-speed broaching machines equipped with advanced controls and tooling systems enable rapid material removal while maintaining tight tolerances. Coating technologies enhance tool durability and wear resistance, prolonging tool life and reducing maintenance requirements. Additionally, innovative approaches such as helical broaching and broaching on CNC machining centers expand the capabilities of broaching tools, opening up new possibilities for machining complex components.

Get more insights on Broaching Tools